Started riveting the VS skin tonight. Nothing like re-honing your riveting skills by starting out with blind bucking, long reach riveting! NOT! So the directions have you pull out the bottom tip rib so you can buck the middle tip rib rivets. Not hard, just awkward! I found the called out -3.5 rivets too long for these as they were too easy to tip, club or cleat over (whatever you call it). The -3 rivets worked fine.

If you do this alone, you have to stick your arm and bucking bar all the way up to the middle rib and feel your way through the process. Using the other hand to run the gun and keep it under control. It is easy to scar up everything in there so be careful. It is also easy to dent the skin with a wild bucking bar so be careful with that as well.

You kind of have to figure out the right way to hold the bucking bar to keep it in check and minimize any damage.

I use a tungsten bar whenever possible. This was another one of my favorite luxury tool purchases when building the RV-7. I wrap it in tape where I can to prevent scratches and dents.

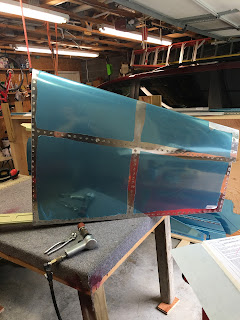

Side one done!

From the outside...

Side 2 done! Love the durability of the AKZO. It will scratch but nowhere near as easy as any of the other primers I have used in the past!

Now the directions have you rivet the top tip rib only to the skin fwd of the spar. Easy peasy with the squeezer! Back to -3.5 rivets here due to the extra control gained by using the squeezer instead of the gun and bucking bar.

Other side!

All done!

Next they have you rivet the bottom tip rib to the skin only....skipping the holes that are used later for the emp. fairing attachment screws.

Side one....easy with the squeezer!

Skip those holes!

Done!

Next will be the blind bucking of the skin to front spar and middle rib. The upper side has to be done by lifting the skin so you can get your arm and bucking bar in there. That is where I stopped for tonight. Had to attend a seminar at our kids school tonight so this work session is short!