Vans directions call for multiple priming sessions on this HS. I want to minimize the number of priming sessions so I am moving forward with more fabrication and match drilling before priming.

Next I had to spend most of my time tonight making these attach brackets out of some heavy angle. Vans gives you some very specific dimensions and they require you to make this part with a weird and unnecessary angle on it making you have to cut it at an angle on one side. You end up making two parts, a left and a right.

While the band saw cuts this stuff fairly well, Vans really should not make builders fabricate such a critical part with such critical dimensions. It took a couple hours to lay these out, cut and file to final size, debur and then drill these suckers. The plans call for dimensions that leave very little room for error. It would be very easy to lose edge distance. This is totally not necessary since there is room to make these larger. Oh well, I just made em per the plans and they turned out ok.

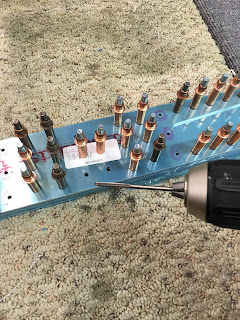

Drilling the locating hole then drilled the mounting holes that will attach the whole HS to the tail cone.

Clecoed the front spar, doubler and used the locating hole to cleco the brackets to the assembly for drilling. Yes I know the spar caps are missing. I just did not want to fool with those tonight. I will go back and do those later.

No comments:

Post a Comment