I did not follow the directions and mount the elevators to the HS on the bench like they tell you to. The only reason I can see they have you do that is to help stabilize the whole mess. My HS is already mounted to the tailcone and I used straps to help keep it stable. So now I am going to mount the elevators.

I made this tool back when I built the RV-7. It works like a dream at installing rod end bearings into nutplates.

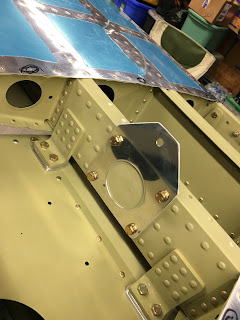

Detail of how it is made on the business end.

The bearing goes in like this. The way it is made, it puts the pressure on the outside of the bearing and not the ball which can damage these things.

Get the bearing started in the hole and twist to the desired depth. Easy peasy!

I installed these exactly per the plans which is 7/8" from the center of the ball hole to the face of the elevator front spar. To make it easier, add 3/8" to that dimension and measure 1-1/4" from the top of the outside edge of the bearing assembly to the front spar face. I used the depth gauge feature of my digital calipers to do this.

Amazingly this worked like a treat! The elevator counterweight ended up perfectly aligned with the HS! No goofing around with the bearings required!