I worked from the center back and forth, alternating left and right sides to prevent warping the whole assembly.

Time to grit my teeth and rivet the trialing edge rivets. It is straight at this point....

I started by squeezing the rivets only part way with two flat sets. This just locks everything together. I started in the middle and skipped every ten holes or so and worked to the end. Then went back and caught the middle hole that was remaining. Rinse and repeat till all the holes had a rivet. Trying to keep it straight!

Then I ground two new flat sets at the trailing edge angle and then final squeezed the rivets. As you can see, this worked really well. These are the shop heads! Trailing edge is done!

As you can see, it ended up very straight. I am happy happy happy with it!

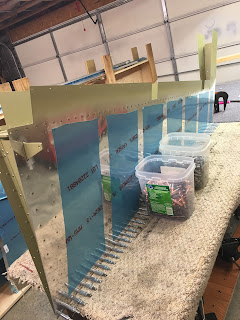

Next is rolling the leading edges. Mostly the pipe is to get it started but the real shapping happens by working it with your hands.

Here they are all bent and clecoed. Some minor massaging took place after this pic.

Then, drill to #30, debur and reflect with 1/8” clecos.

No comments:

Post a Comment